The growth of robotics and automation in warehouse management is accelerating exponentially. Driven by the rise of e-commerce and omnichannel retail—which has created a demand for faster, more efficient warehouse operations—companies are exploring robotics automation to help them optimize their supply chain operations, increase productivity, reduce costs, and gain a competitive advantage.

Next-Level Warehouse Automation for Optimized Performance

To meet the rapidly growing needs of robotics and automation in warehouse management, Netlogistik utilizes the SOFTBOT® Platform from SVT Robotics. This tech-agnostic platform revolutionizes how our customers can apply robotics automation seamlessly into their existing systems. Integrating the SOFTBOT® Platform with logistics and distribution solutions enables our clients to deploy and manage advanced robotic systems efficiently. These systems include sortation, picking, packing, inventory management, automated mobile robots (AMRs), put-away systems, vision systems, and more, enhancing operational efficiency and agility in their warehouse processes.

SOFTBOT delivers the integrations and visibility today’s supply chains need

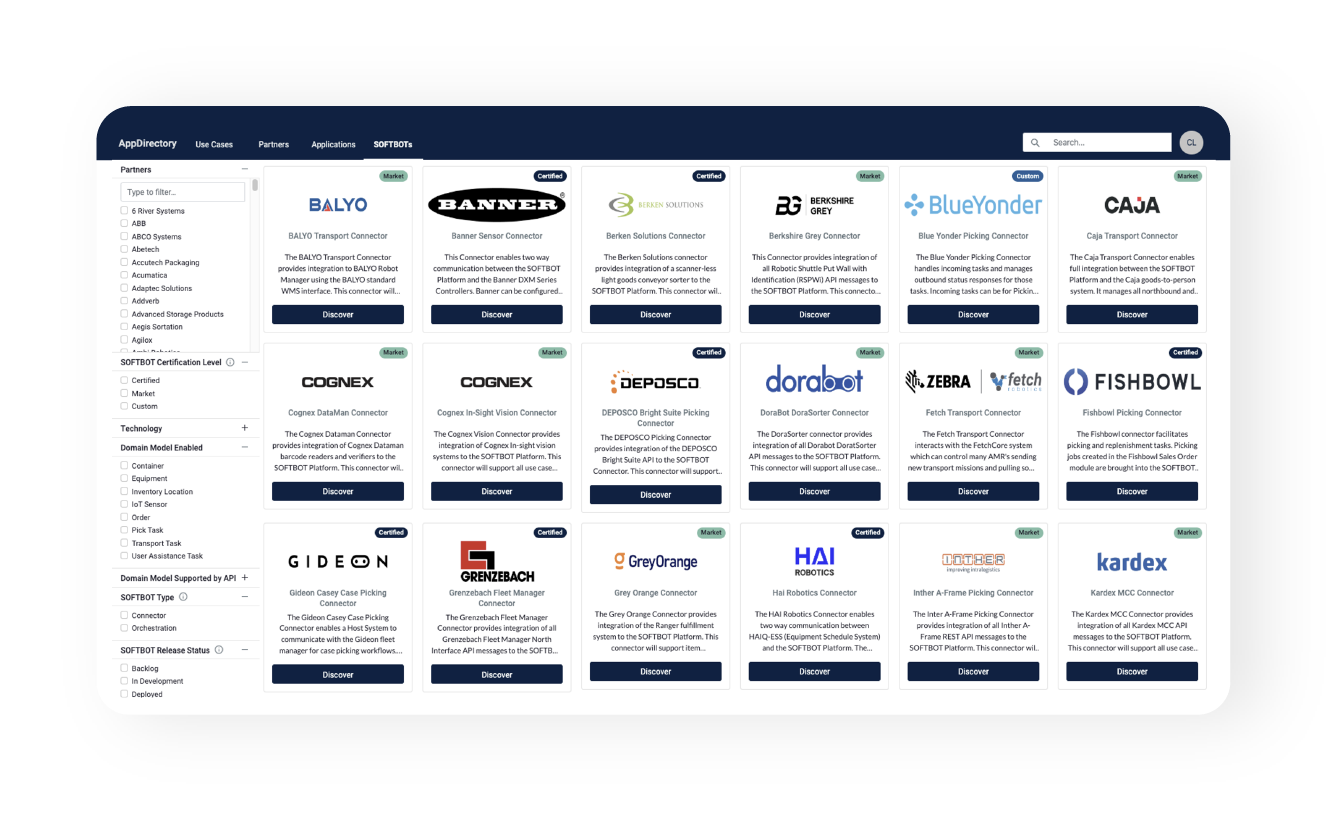

SOFTBOT helps companies solve integration challenges by offering reusable integrations ready to deploy with no custom code required. The Platform can also aggregate and normalize data from disparate systems and display them in a single location, providing end users real-time auditing and monitoring capability across technologies.

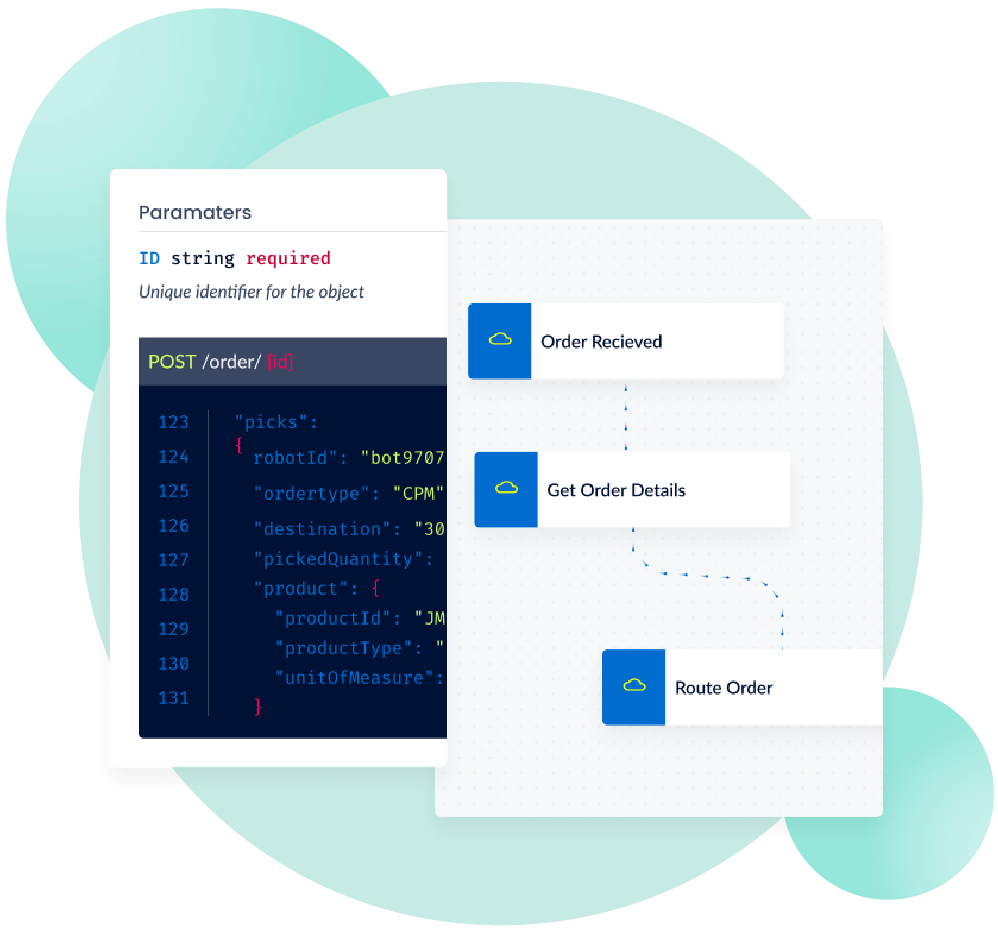

SOFTBOT® Integrate

Enable real-time interoperability with prebuilt and reusable integrations.

-

Minimize project risk with proven integrations

-

Reduce IT burden when adding new solutions

-

Leverage pre-built SOFTBOTs in production and test environments

-

Choose your deployment architecture—customer or cloud-hosted

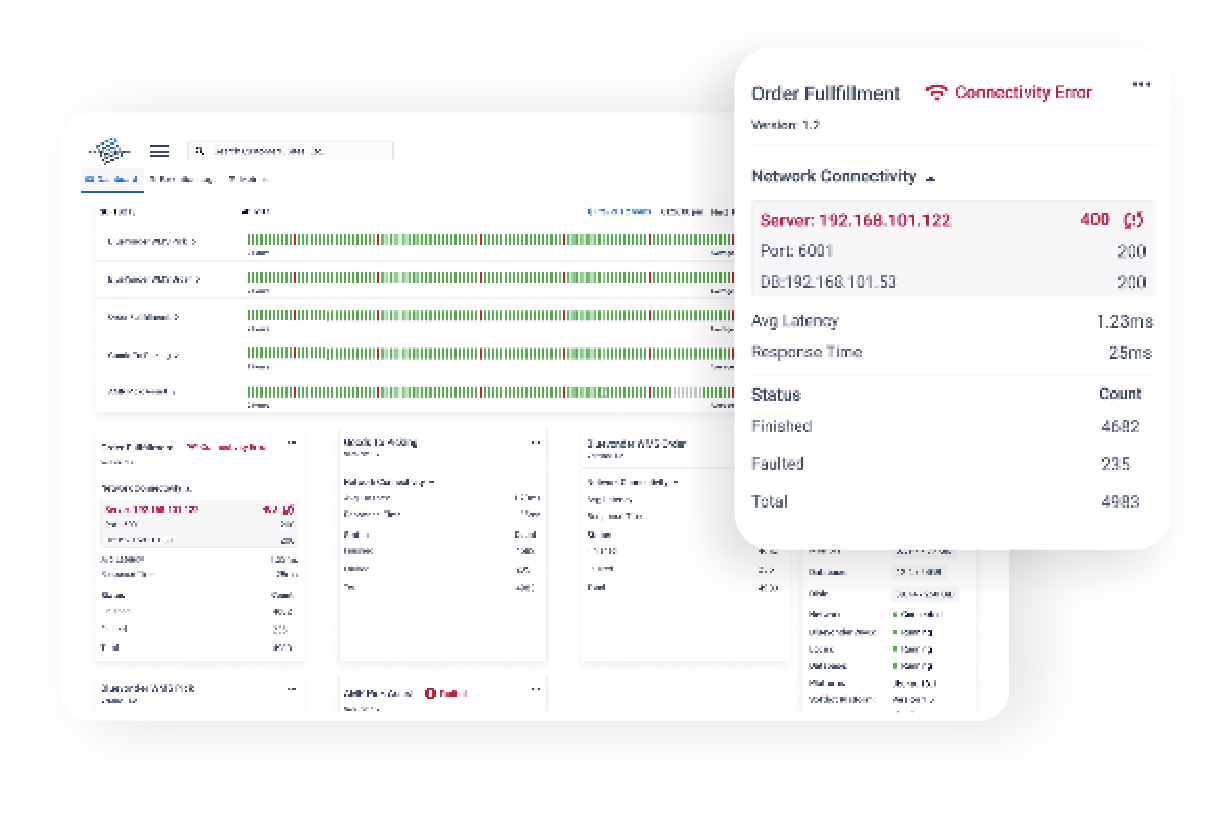

SOFTBOT® Monitor

Ensure quick resolution of any impacts to operational throughput.

-

Get real-time visibility into system performance

-

Detect issues early with alerting capabilities

-

Quickly troubleshoot issues for faster resolution

-

Get access to aggregated supply chain data

SOFTBOT® Build

The ultimate toolset to integrate, monitor, and scale automation.

SOFTBOT Build provides the toolset to customize or build new SOFTBOTs to create interoperability with other technologies on the SOFTBOT Platform

What makes Robotics Automation such a powerful offering for warehouse management?

Integrating warehouse robotics with WMS software has helped a wide range of businesses—including those in the retail, e-commerce, and manufacturing industries—realize several important benefits that significantly impact warehouse operations. Such benefits include:

Increased productivity

and efficiency:

Warehouse robots can perform repetitive tasks 24/7 without fatigue, increasing productivity and throughput while minimizing process bottlenecks.

Earlier defect

detection:

By automating potentially hazardous tasks such as storing, picking, and packing heavy goods, warehouse robots minimize the potential for accidents and injuries while helping improve overall risk management.

Reduction in

labor costs:

Warehouse robots decrease the need for manual labor, resulting in cost savings.

Improved accuracy and

order fulfillment:

Warehouse robots can be equipped with advanced sensors and algorithms to ensure precise picking, sorting, and packing of items. This reduces the risk of errors and improves order fulfillment accuracy.

Real-time visibility into

system performance:

Automated robots can provide actionable insights for improving warehouse operations. Integrating robots with WMS software lets you easily view the latest data and insights via a user-friendly display

Discover more robust solutions to transform your operation.

-

-

-