Warehouse Management System by Blue Yonder

The exact inventory at the correct location, right on time

Warehouse Management System by Blue Yonder

The exact inventory at the correct location, right on time

WMS leader in the 2024 Gartner Magic Quadrant

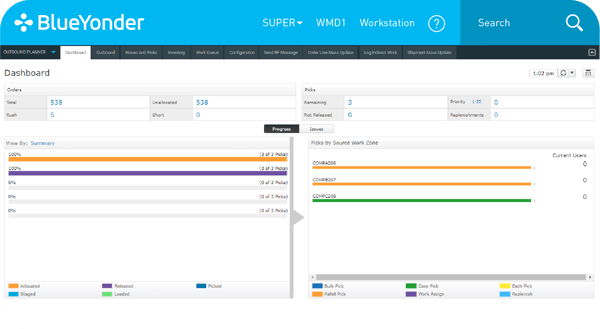

Pave the way into the digital era with Blue Yonder's Warehouse Managment and transform your operation into a digital environment. Blue Yonder’s WMS empowers you to deliver high service at a low cost. Seamlessly integrate task management and labor standars while optimizing storage, selection strategies, and yard management.

Why should you choose Netlogistik to implement WMS by Blue Yonder?

We are one of the only five partners that hold the "Global Advanced Company Accreditation for Warehouse Management".

Why should you choose Netlogistik to implement WMS by Blue Yonder?

We are one of the only five partners that hold the "Global Advanced Company Accreditation for Warehouse Management".

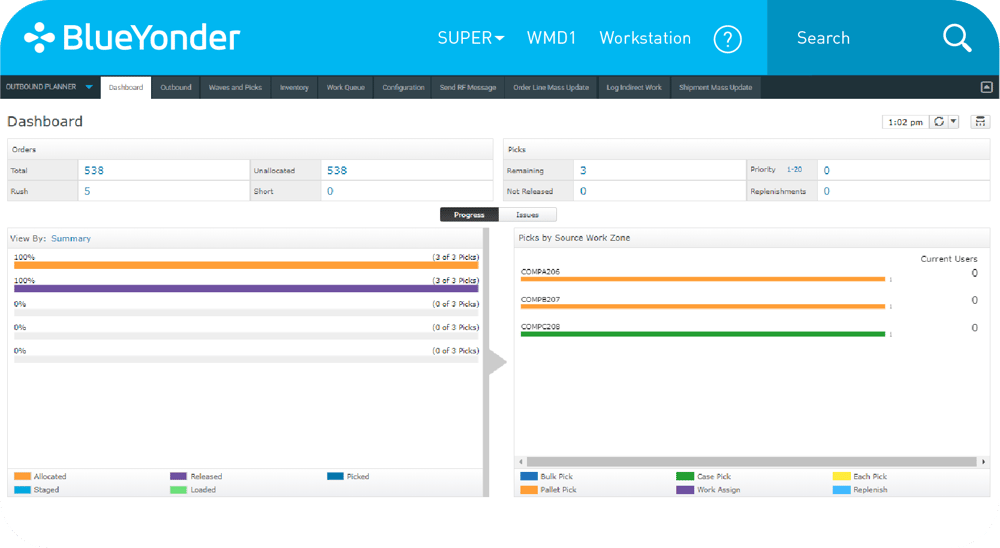

Warehouse Management

Digitalize your distribution center and manage all processes efficiently.

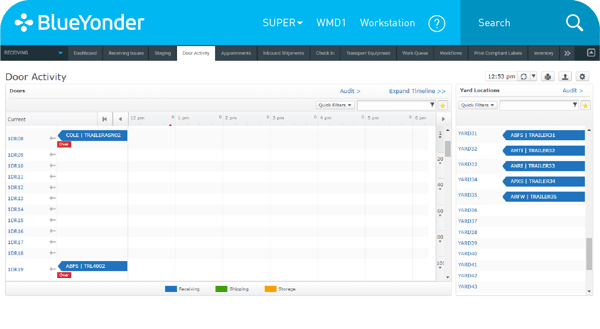

- Unified yard management

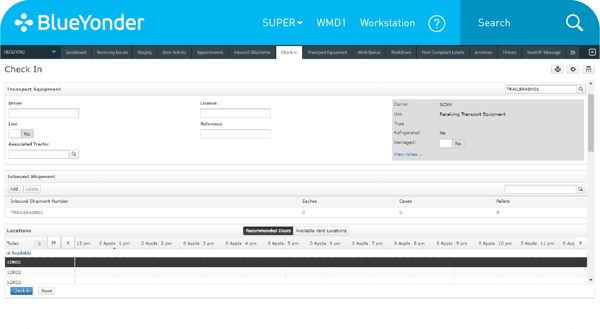

- Inbound processing

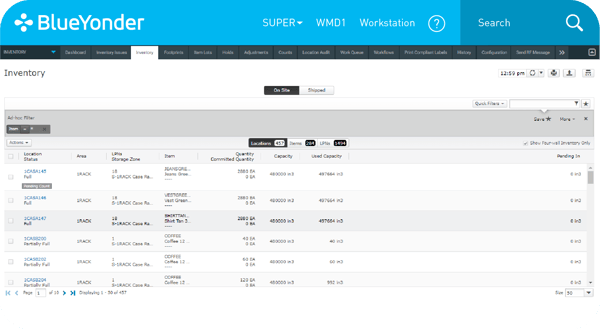

- Intelligent inventory management

- Intuitive & configurable warehouse tasking

- Outbound processing

- Workforce orchestration

- Shippers

- Usability

Seamlessly orchestrate all yard tasks, including equipment, dock doors, and personnel

|

|

Streamline operations and optimize tasks by gaining visibility into inbound shipments

|

|

End-to-end visibility through effective inventory management, from supplier to user

|

|

Easily manage even the most complex warehouse through flexible, real time predictive and prespecitve workflows

|

|

Agile outbound proccessing

|

|

Boost performance standards and automation by tracking labor and scheduling across operations

|

|

Coordinate orders with your shippers

|

|

Intuitive and configurable user experience

|

|

- Unified yard management

- Inbound processing

- Intelligent inventory management

- Intuitive & configurable warehouse tasking

- Outbound processing

- Workforce orchestration

- Shippers

- Usability

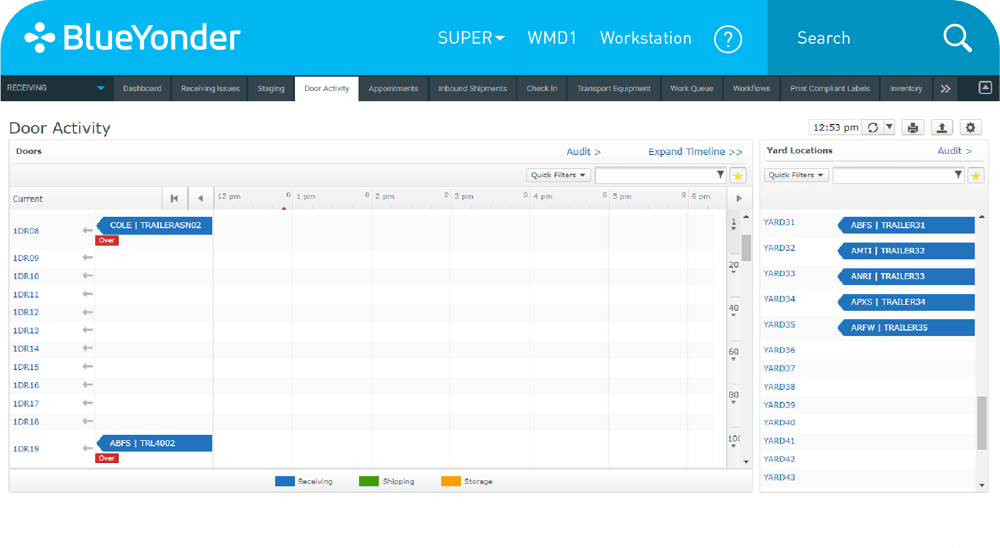

Seamlessly orchestrate all yard tasks, including equipment, dock doors, and personnel

-

Registry of entrances and exits at the door

-

Clear location of items in the yard and assignment of loading docks

-

System-directed movements via wireless devices

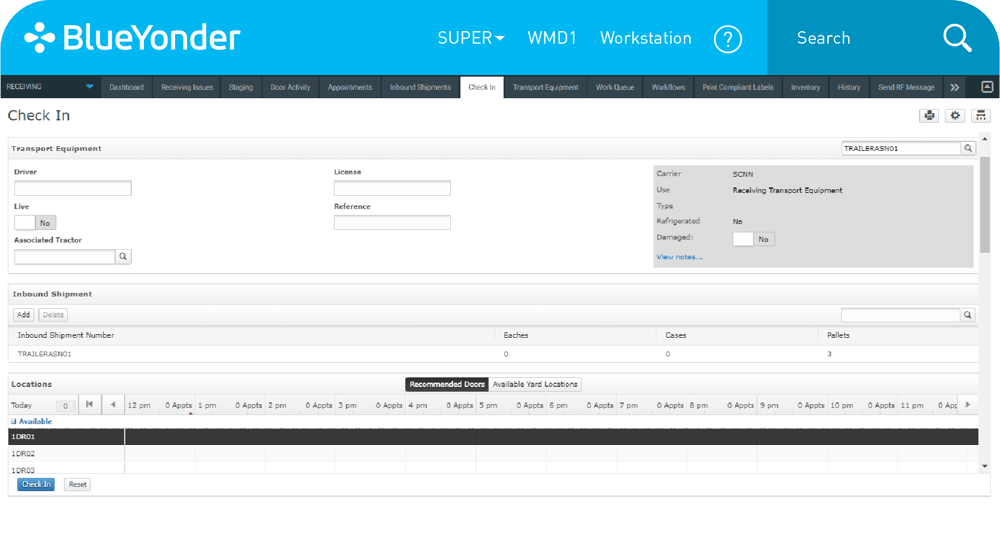

Streamline operations and optimize tasks by gaining visibility into inbound shipments

-

System-suggested storage locations

-

Cross-docking that identifies critical loads with priority inventory

-

Fast returns processing to speed up reverse logistics

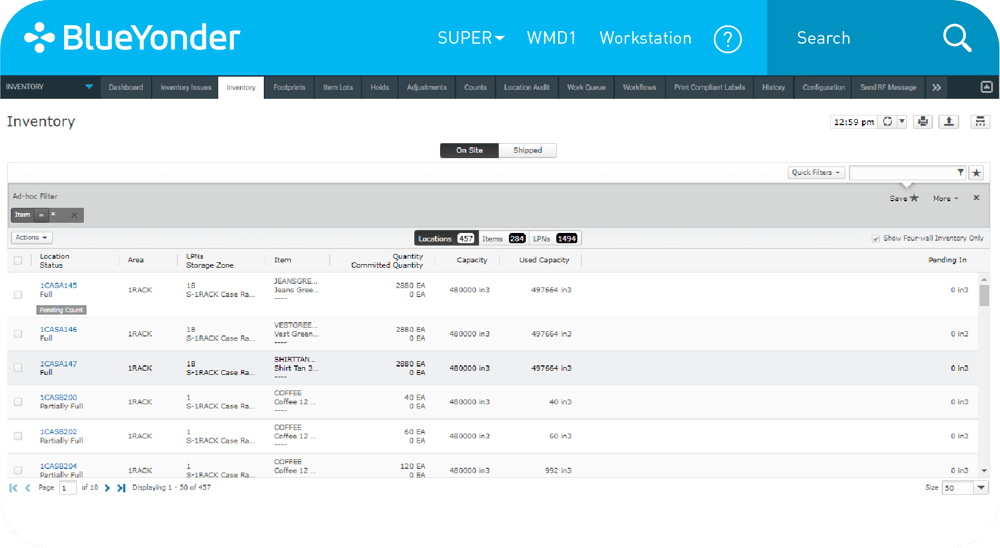

End-to-end visibility through effective inventory management, from supplier to user

-

Traceability of products at all times

-

Inventory control according to quality, expiration dates, serial number, asset management, and cycle count

-

Eliminate the use of paper and manual processes

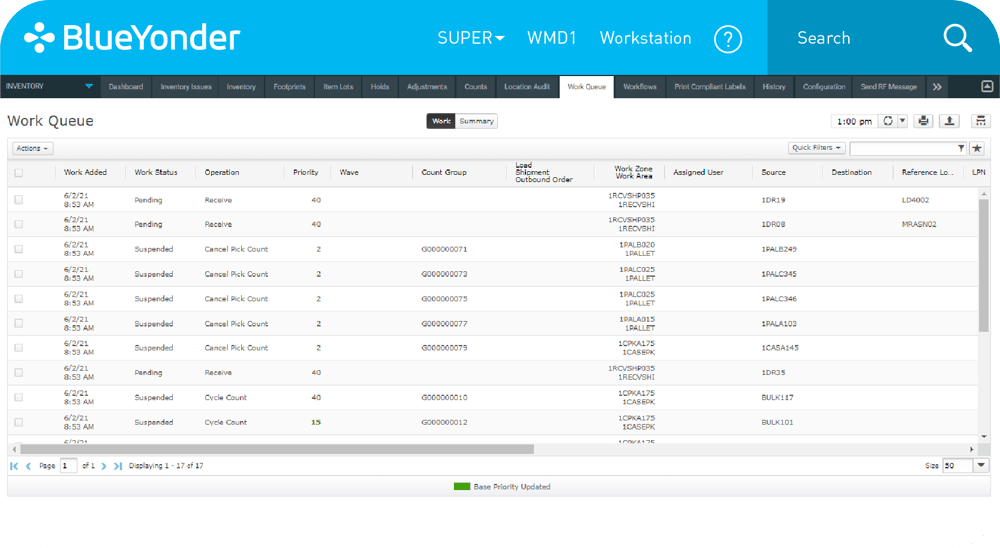

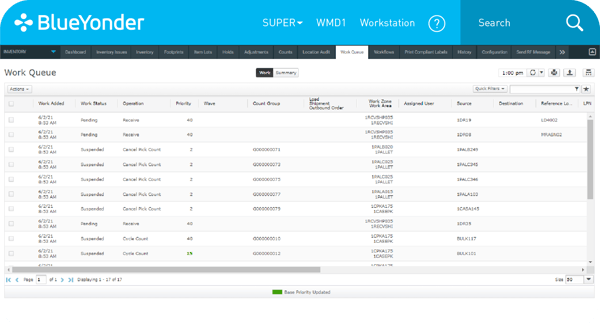

Easily manage even the most complex warehouse through flexible, real time predictive and prespecitve workflows

-

Intelligent correlation between tasks and committed service level

-

Management of all tasks in a single work queue

-

Machine-learning-adjusted tasks and priorities to obtain the best possible result

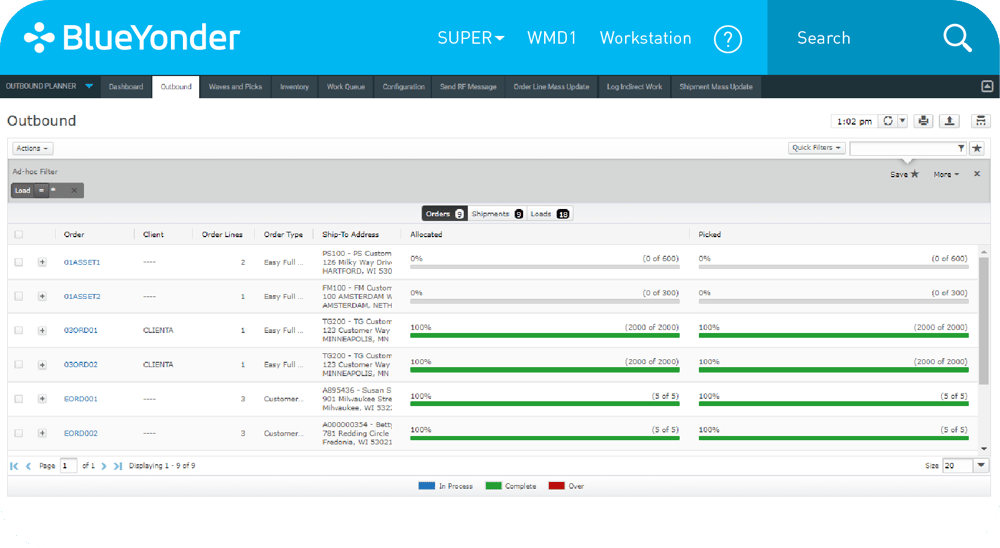

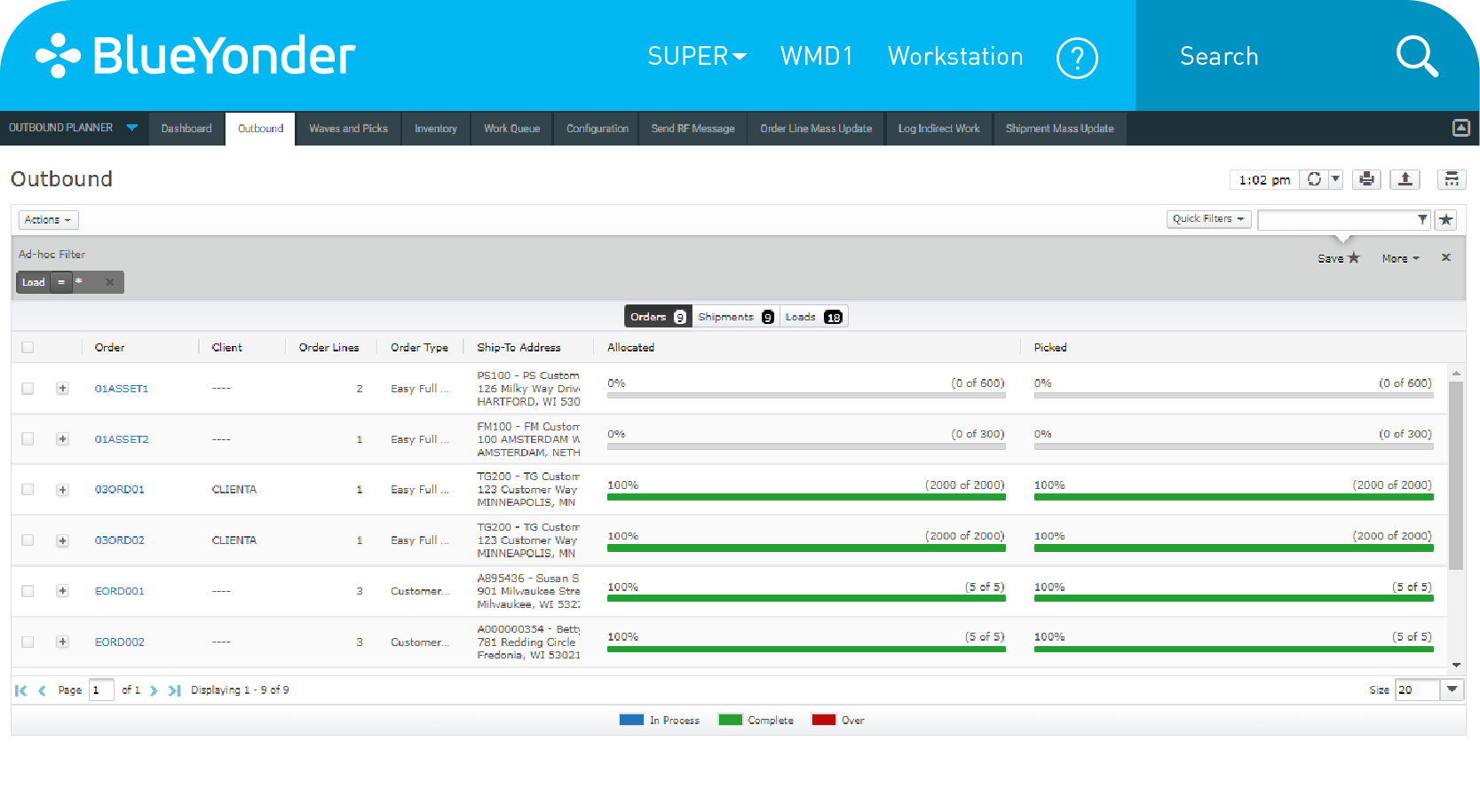

Agile outbound proccessing

-

Support for/on multiple picking methods to reduce travel time and increase efficiency

-

pack station through touch screen and scanner to capture barcode, lot and serial number

-

Cartonization for synchronization with carriers and order consolidation

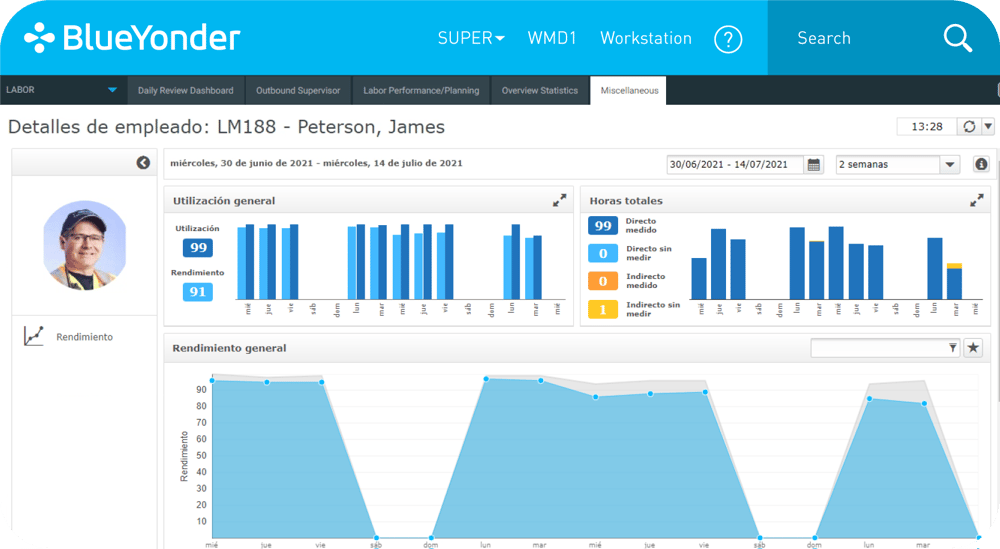

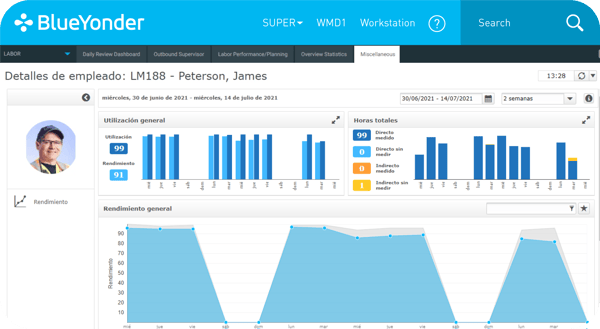

Boost performance standards and automation by tracking labor and scheduling across operations

-

Integration with Blue Yonder Labor Management System

-

Dynamic determination of the operators' tasks

-

Advanced future planning of staff needs

-

Set-up of task escalation priorities based on permissions and proximity

-

Task performance measurement and productivity reports

-

Trend analysis for the use of equipment and facilities

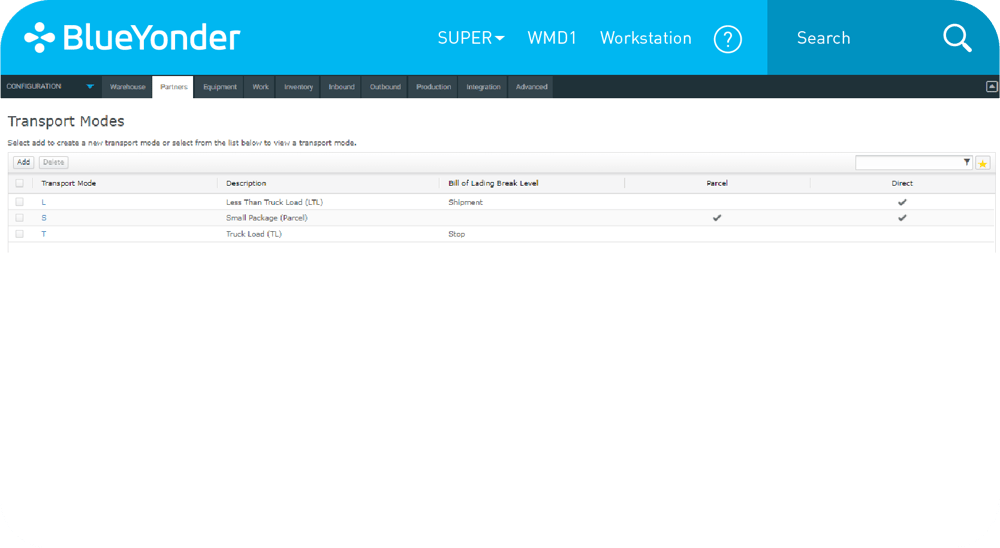

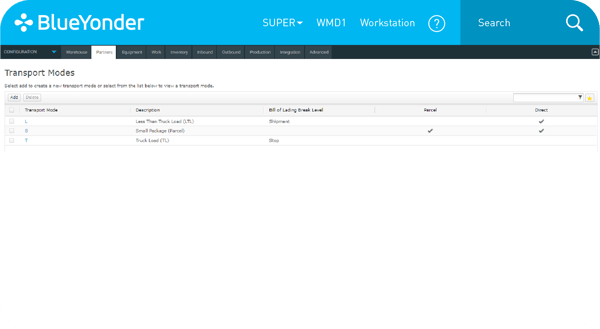

Coordinate orders with your shippers

-

Support with small packages, LTL and international operations

-

Selection of the best carrier based on the customer's rules and priorities

-

Tracking and traceability of functions through a direct link to the operator's website

Intuitive and configurable user experience

-

Greater flexibility and responsiveness in real time

-

Prescriptive and mobile workflows to easily manage complex warehouse operations

-

Simplified integration with other systems (TMS, Labor Management System, e-commerce, etc.)

Some of our global clients

El objetivo más significativo para nuestra organización era lograr una estabilidad operativa. Desde la implementación del WMS de Blue Yonder de la mano con Netlogistik, hemos conseguido esa estabilidad.

Virgilo Paniagua Guadarrama

Director de Logística y Servicios Especiales

jjjj

El objetivo más significativo para nuestra organización era lograr una estabilidad operativa. Desde la implementación del WMS de Blue Yonder de la mano con Netlogistik, hemos conseguido esa estabilidad.

Virgilo Paniagua Guadarrama

Director de Logística y Servicios Especiales

Frequently asked questions

How does the process of implementing a WMS work?

The implementation process of a WMS must be drawn out according to the client’s needs and must be carried out through a proven methodology that minimizes risks and guarantees the success of the project. Typically, implementing such a system takes between 3 and 6 months, depending on the operation.

Can a WMS be implemented remotely?

In the past, this would have seemed impossible; however, the COVID-19 pandemic has taught us to work 100% remotely on implementation projects. The Netlogistik team offers this new remote work-practice, largely due to our vast experience. It also represents a significant cost reduction for our clients.

How much experience does Netlogistik have implementing Blue Yonder's WMS?

We have over 110 certified consultants and developers fully dedicated to Blue Yonder’s WMS and TMS. With 400 warehouses successfully implemented worldwide, we have been recognized by Blue Yonder for our sales volume, our ability to achieve successful implementations, and because we adhere to the best international standards.

Does the Blue Yonder WMS integrate with other systems, such as ERP or e-commerce?

Yes, there is a middleware called "Integrator" that manages incoming and outgoing transactions, and ensures that the information is transmitted correctly. The Blue Yonder integrator can easily communicate with any other systems, legacy or in-house, such as ERP, WLM, TMS, among others.

How can WMS help my dark store?

The Blue Yonder WMS helps to improve the level of service in the online store orders: among other tasks, it synchronizes the order status and manages the inventories in real time with the internet portal.

How does Netlogistik handle customer support?

With over 21 years of experience assisting in highly complex operations worldwide, Netlogistik has a robust support area. More than 98% of the tickets raised are attended directly by our support team; only the remaining 2% is escalated to Blue Yonder. In less than 24 hours, we provide on-site help and, in a crisis, we have the ability to make support deployments, also on site.

Discover more solutions to grow your business and transform it into a digital environment

-

-

-